Brewing a better world

WHO would have known that the green colour on a Heineken bottle, can and logo is more than just a shade. Although the green does not bear any official connotation, per se, it ideally depicts the “green strategies” Heineken upholds and practises.

In 2007, Heineken, one of the largest beer brewers in the world, decided to take up a global strategy to make environmental sustainability a business imperative. It was understanding that business and environmental sustainability were cardinal in establishing a successful commercial entity, that the global company introduced “Brewing a Better World (BaBW)”.

BaBW is basically an action plan or strategy the company established to mitigate the impact of the it’s business operations on the natural environment. Among its primary focus areas are:

▶ Protecting water resources;

▶ Reducing carbon emissions; and

▶ Sourcing sustainably.

The focus on long-term sustainability heralds a new era for Heineken where profit and environmental targets go hand in hand. To date, ahead of its 2020 aim to become the Greenest Brewer in the World, Heineken already reports significant reductions in water usage and carbon emissions. Ensuing, Heineken Malaysia Berhad shares about its efforts in reducing its carbon and water footprint.

PROTECTING WATER RESOURCES

Water plays an important role in producing beer. Besides being a key ingredient (over 90% of a glass of beer is water), it is essential in other aspects of the beer-making process like cleaning, boiling and pasteurisation.

Heineken Malaysia Berhad supply chain director William Mathers (pix) said that although some areas in the world are more stretched for water than others, Heineken is focused on protecting water resources and reducing its water footprint wherever it operates in.

In Malaysia, among the things that the company has put into practice in reducing its water consumption is through its bottle washing process, as it uses returned bottles. “One of our sustainable practices includes using returned bottles. We wash them to ensure it’s sterile and clean before we refill it again,” shares Mathers.

While using returned bottles also cuts impact to the environment, in 2007, the brewery is reported to have spent 22m3/hour of water simply to wash bottles (that’s about 10,000 litres of water every hour). “The first thing we did – and this is common to how we approach all problems – we restored the equipment or machine to its basic condition or how it was supposed to operate when we bought them.” By doing that, Heineken managed to reduce water usage from 22 m3/hour to 9m3/hour. “But we weren’t content with that. So we looked at how the manufacturers had decided that we should be using the machine and we questioned why they had a 2mmnozzle (which goes up into a bottle to wash out the residue).”

As the size of the nozzle basically determines the amount of water that comes out from the nozzle,“we changed that to a 1.5mm (smaller) nozzle, which reduced the amount of water and altered the pressure to ensure that we get the same cleaning effect, ”Mathers informed. The change in nozzle size further reduced the company’s water use significantly, to 4.5 m3/ hour in 2016.

To ensure it kept to its new lower water usage levels, trigger points were set up all through its operations to keep track. Every step of the brewing process operations is also monitored to prevent wastage, from its forecasting (to better control the use of resources like water and energy), to production planning (better planning to reduce frequency of a specific action like cleaning, which saves water) even packaging (recollecting and reusing water, which is used for pasteurisation).

REDUCING CO2 EMISSIONS

With CO2 being the main driver of climate change, Heineken also undertook minimising emissions every step of the way. Its strategy: reduce the energy (fossil fuel) consumption, thus lowering the amount of CO2 produced. Ultimately, the company focused on two aspects – electricity and thermal energy.

By 2016, Heineken managed to reduce its electricity usage to 12.2% and thermal energy by 17.2% since 2014.

Again, the first action was “to ensure that things were restored to its basic condition,” shared Mathers. Among other areas it addressed were simple things like ensuring the correct power ratings were being used on different pumps and that suitable pumps were employed for specific tasks – basically, not overplaying or underplaying the equipment and use of electricity. “We also installed lights and switches on our conveyers so it does not continue to run if there is nothing on them. It gets switched off.”

Other strategies Heineken took up to reduce its CO2 emissions include:

1.Eliminating compressed air leaks;

2. Optimising creation and usage of thermal energy;

3. Recovering and reusing energy; and

4. Increasing efficiency in distribution.

SOURCING SUSTAINABLY

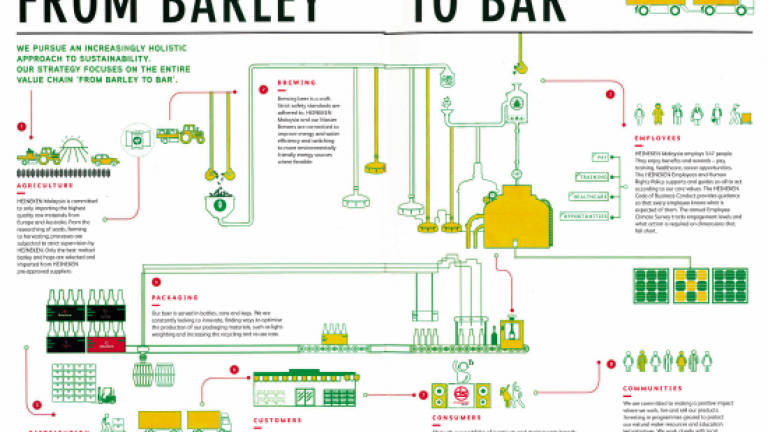

Heineken works closely with its suppliers, locally and around the world to ensure it is acting responsibly and sustainably. “To brew our beer, we use malted barley and hops, which we import from Africa. We have a number of programmes there where we work with local farmers to ensure that we create some sustainable income in their local communities. We also help them plant the right crops, which we then buy and make malted barley,” tells Mathers.

Besides raw ingredients, Heineken also puts emphasis on its packaging materials i.e. cans, bottles, labels, etc. In addition to continually looking for the best source for these materials, the company works closely with the manufacturer, to optimise the sustainability of their processes. “For example, our bottles are made in Johor. We work very closely with the supplier to try and optimise the amount of glass used to make a bottle,”Mathers explains.

In 2016, 85% of its suppliers have signed the Heineken Supplier Code and Heineken Malaysia’s Supplementary Code. “Sourcing sustainably has an impact on the environment but we also try to ensure that we have good partnership with our suppliers. Importantly, we expect our suppliers to operate at the same way we do, with integrity and have good business conduct as well as respect for human rights and environmental sustainability,” Mathers declares.

For more information on Heineken’s green practices, visit its official website.