KUALA LUMPUR: The Fourth Industry, the Fourth Revolution, Industry 4.0 or Revolution 4.0 – they are all the same thing and we need to keep up with it.

But what is it? To put it simply, it is the new approach to combining traditional manufacturing processes and technology such as the Internet of Things (IoT) to improve automation, communication and use of real-time data.

The IoT refers to the billions of physical devices around the world that are now connected to the internet, collecting and sharing data. It touches on almost every aspect of our daily lives.

This is different than during the first industrial revolution which focused only on the use of steam-powered machinery, the second industrial revolution which focused on electrics and the third industrial revolution that leaned on the usage of information technology (IT).

It used to be that televisions functioned only as a medium to disseminate information and provide entertainment to the masses. Today, however, a smart television can detect if those watching it have fallen asleep and switches itself off automatically.

This is an example of how technology, under Revolution 4.0, can tread the line between humans and machine.

Smart homes, smart cars and smartphones are just a few examples of how automation and real-time data are used under Revolution 4.0.

The industrial revolution

The term Industry 4.0 was said to have been used in Germany as early as 2011. However, it only started to gain attention when it was announced during the 2016 World Economic Forum that the world was at the threshold of the fourth industrial revolution.

A senior lecturer at Universiti Kebangsaan Malaysia (UKM)’s Department of Electrical, Electronic and Systems Engineering, Associate Prof Dr Sawal Hamid Md Ali said that the key to the industrial revolution started in the 18th century with the advent of steam-powered engines.

Steam was used to power locomotives and subsequently facilitated major advancements in manufacturing and transportation, among others, resulting in the Industrial Revolution 1.0.

Then, right before World War I, scientists discovered electricity which propelled the Industrial Revolution 2.0, leading to the invention of telephones, aircraft and other vehicles using internal combustion engine.

“With electricity, production could be done on a mass scale, leading to the creation of factories for manufacturing,“ he explained to Bernama.

Industry 3.0 emerged in the late 1960s. It is also known as the digital revolution as it is when electronic devices like cameras, televisions and radios were invented. The development of the internet technology also happened during the era.

Industry 4.0 is said to be based on the digital revolution. However, what distinguishes it from Industry 3.0 is the connectivity between digital technology and humans as well as other physical systems.

“Industry 4.0 is about cyber-physical systems and systems that can connect the digital world with biological systems like humans through the internet.

“In Industry 3.0, the technology doesn’t communicate directly with humans but with Industry 4.0, there is a two-way connection between humans and electronics. This makes humans a part of technology.

“Electronic devices use the data derived from humans to execute its functions better. This is what’s happening with smartphones, smart TVs and smart homes,“ he explained.

The speed of technology

Malaysia is among the countries forging ahead with the Industrial Revolution 4.0.

One of the core technologies of Industry 4.0 is Artificial Intelligence or AI. Through AI, a system is created to learn from its surroundings and use that data to connect humans, physical tools and the digital world.

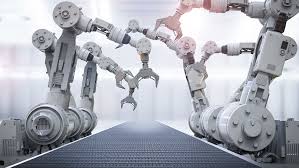

Another core technology is the robotic process automation (RPA), which is the use of software with AI and machine learning capabilities to mimic human workers, particularly at doing high-volume, repetitive tasks.

Other Industry 4.0 technology are Cloud Computing technology for storing and processing data, IoT that connects a device to smart senses using internet connection, cyber security that protects data and minimises risks and 3D printing that facilitates the production of prototypes.

Other technology involve Virtual Reality which provides visual information in a virtual format, Augmented Reality which combines the physical world with the virtual world and Big Data Analysis which uses collected data to provide service or come up with accurate projections.

Sawal Hamid said that the development and progress of Industry 4.0 depended on the usage of internet technology and big data analysis to propel manufacturing, services and businesses.

“If internet access is not readily available nationwide and the speed is limited, it would adversely affect the development of Industry 4.0.

“The success of (ride-sharing and e-hailing app) Grab, a home-grown service, is an example of the dependence on internet technology for advancement. Malaysians are already ready to become a player and mobiliser of this new revolution,“ he said.

Although Malaysia is still a consumer country, it could very well be on its way to becoming a manufacturing country if access to information is made easier through good and affordable internet access.

It can help the community develop a system, app or service utilising, for example, AI and in turn, avail opportunities to others by creating new business models.

One of the mobilising factors of Industry 4.0 is the high processing power coupled with digital storage that drives the manufacturing of high technology products.

“With high processing power, even a small smartphone can run a variety of functions. Today, smartphones are equipped with AI processing which uses data from the surroundings to function better. For example, when taking a photo with our smartphone, AI will automatically assess the surroundings to enable the capture of better pictures.

“The high processing power, as well as high data storage capabilities, is the catalyst for the Fourth Revolution,“ he said.

Highly-skilled and creative

However, many have voiced their concerns about robots taking over human tasks.

Low-skilled manpower like manufacturing operators is among the jobs that would probably be on the line as they are gradually replaced by robots of other computerised systems.

However, highly-skilled manpower to design, develop software and AI and run programmes would be in demand in Industry 4.0.

“Perhaps we may no longer need that many labourers but there is and will be a demand for highly-skilled manpower in the current and future job market,“ he said.

The education system needs to reflect these changes. Students need to be exposed to Industry 4.0 from the primary level.

Students need to be taught in detail how to develop a technology using codes and algorithms. App development, which can be learned from a very young age, need to also be taught in schools.

“The early exposure can help us develop skilled manpower that caters to the job market. Most of this knowledge can easily be learned for free through the internet,“ he said.

Need to change

These rapid changes in the industry require society to change and be part of those mobilising Industry 4.0.

Sawal Hamid said that if they were reluctant to do so on their own, they would find themselves forced to adapt to the changes anyhow.

The e-hailing app Grab, for example, ‘disrupted’ the services of conventional taxis and streaming service Netflix bankrupted video rental service Blockbuster.

“The present technology changes the conventional and those who refuse to keep up will be eliminated by the new technology.

“Technology moves at breakneck speed and the whole world is keeping up with its pace. If we don’t work at it, other countries in the region like Indonesia, Thailand and Vietnam will easily overtake us and leave us behind,“ he said. — Bernama