KUALA LUMPUR: The Taiwan Excellence, recognised as the industrial Oscar award of Taiwanese products, set up the Taiwan Excellence Pavilion within the Taiwan Expo 2023 in Malaysia. The pavilion showcased nearly 60 innovative products from 33 brands, highlighting the prowess in high-quality manufacturing that Made-in-Taiwan (MIT) brings to the table.

One of the Taiwan Excellence companies is Everplast Machinery Co Ltd introducing its Cement Extrusion 3D Printer at the Expo.

Everplast vice-general manager Denny Huang told SunBiz that this 3D printer offers a sustainable and eco-friendly approach to building structures.

“This 3D printer brings a sustainable and eco-friendly revolution to the construction industry. In addition, the feature of this model is that it is small, making it suitable for labs and producing small objects. It is easy to assemble, disassemble, use and clean,” he said.

The printer’s versatility in working with diverse cement formulations including recycled materials, addresses waste reduction and ecological concerns.

“We can also add waste material like oyster shells. Our ongoing tests encompass an array of waste materials such as green clay, waste paper pulp, waste slag, waste gypsum board, and more, where we can help environmental causes,” he said.

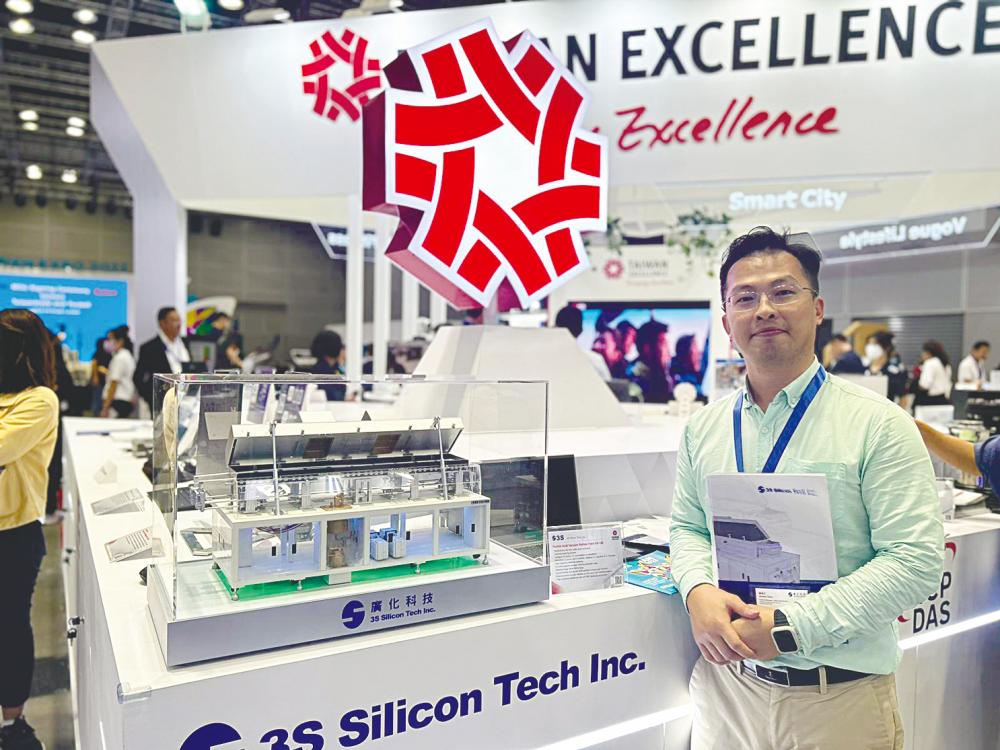

Another Taiwan Excellence company, 3S Silicon Tech, is revolutionising electronics production with its Formic Acid Vacuum Reflow Oven.

Formic acid vacuum reflow oven is a soldering and semiconductor component packaging machine.

3S Silicon Tech Inc sales and marketing director Eason Liu told SunBiz that this machine makes electronics manufacturing faster, cheaper, safer, and better for the environment, while creating high-quality parts.

“Because we are the only one in Asia making formic acid solution, we have the chance to cooperate with the world’s top manufacturers such as Infineon in Malacca. We are now co-operating with them for a new automation production platform for their next generation IGBT device.

We’re also in the process of offering a similar solution to other customers who have similar needs as Infineon. Our aim is to partner with Malaysian companies and share our production expertise to help them achieve successful outcomes,” he shared.